Creating a bigger model train layout is exciting. When the tracks are increased, the possibilities of encountering electrical problems increase. Even minor failures can lead to disappointment and impact the performance of your trains, ranging from power drops to short circuits. The positive aspect is that these issues can be avoided with proper planning and arrangement.

Avoid Common Electrical Issues in Larger Model Train Layouts

Plan Your Power Distribution.

The most frequent error in larger layouts is when one power connection is used. This causes an uneven voltage and poor train performance. To prevent this, install a bus wiring system, a central pair of wires that runs below your layout with the feeder wires attached to the track at regular intervals of a few feet. This ensures uniform power throughout the system.

Prevent Voltage Drops

Long runs of track may lead to loss of voltage when you do not have a dual connection to supply power. To avoid this, ensure that your feeders are spaced out evenly. Besides, you have to use the correct wire gauge. Use heavier bus wires (such as 14 to 16 gauge) where the layout is bigger. Use smaller feeder wires (18 to 22 gauge) to attach the track to the bus.

Look Out for Loose Connections.

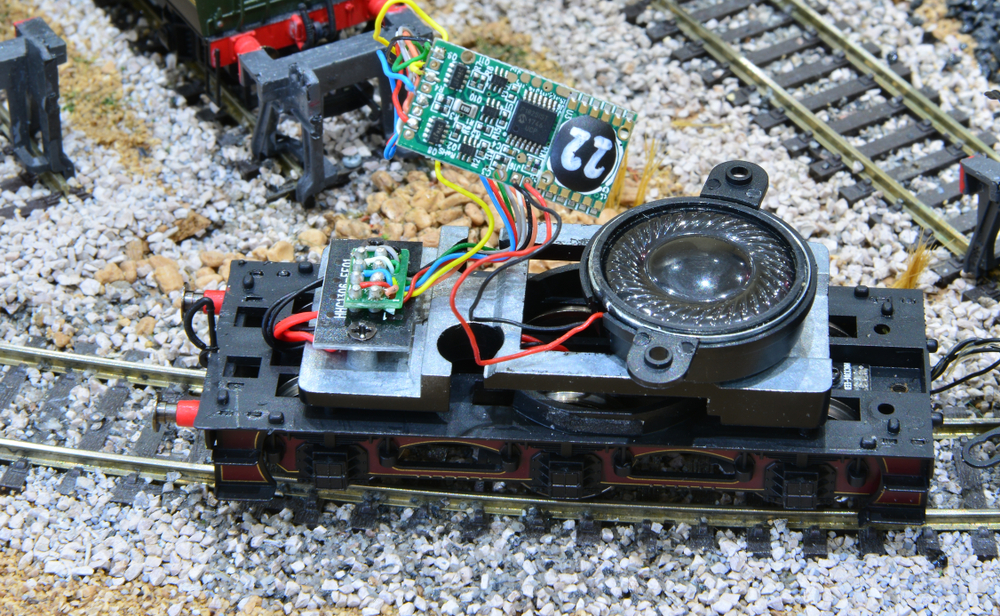

Connections can be loose or soldered poorly. It can cause trains to stall or flickering lights. It is always important to check that your wires are securely fastened, and it is possible to use solder as a more permanent fix. If soldering is not possible, use high-quality connectors to maintain contact.

Manage Short Circuits

Another common problem is short circuits, particularly during work with complicated track plans. These may be a result of reversed wiring or objects made of metal crossing the rails. Short circuits can be isolated at critical points by installing insulated rail joiners, and a circuit breaker or power district arrangement can be used to resolve them before they damage your equipment.

Keep Wires Organized

Wiring may easily be a mess with larger layouts. This not only makes it hard to troubleshoot, but it also increases the chances of error. To make everything easy to handle and maintain, use cable ties, colored wires, and labels. This little move is time- and stress-saving in the long run.

Test as You Build

Rather than waiting until the entire layout is finished, test your electrical system during the building process. Test run trains over shorter distances. So that the power is consistent and to identify possible issues promptly. This incremental process identifies and corrects the problems.

Ready to Wire Your Model Train?

With proper planning, system organization, and testing along the way, you can avoid most of the typical electrical problems and have a smoothly running layout. The team of Charles Ro has the knowledge and experience to point you in the right direction. Whether it is a simple design or a complex wiring system that needs troubleshooting, our staff ensures your trains are on the tracks and cause no headaches. Looking to handle the wiring on your own? Check out our online store!